- Home Page

- Company Profile

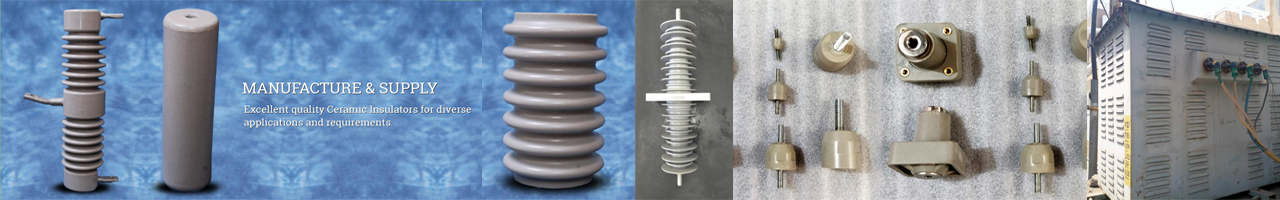

-

Our Products

- Fuse Cut Outs

- Electrical Disconnector

- Transformer Bushing

- Support Insulators

- Cable Connectors

- Gas Insulated Switchgear

- Voltage Detectors

- Switchgear Products

- Terminal Plate

- Electrical Bushing

- Electrical Insulators

- Polycrete Insulator

- 22kV Epoxy Support Insulator

- 11KV Epoxy Support Insulator

- 110kv Fuse Cut Out Insulators

- Support Insulator For Switchgears

- High Voltage Electrical Isolator

- Medium Voltage Insulators

- High Voltage Insulators

- Epoxy Low Tension Insulators

- Epoxy Cast Support Insulators

- Epoxy Switchgears Insulators

- 400VA Fuse Cut Out Insulator

- Fuse Cut Out Insulators

- Railway Insulators

- 25 kV Pantograph Insulator

- 25kv Roof Railway Insulator

- 25 kv High Voltage Bushing

- Third Rail Insulators

- Light Railway Insulator

- Railway Rooftop Insulator

- Light Rail Insulators

- 25KV Roof Top Bushing For Railways

- Pantograph Support Insulators

- 33kv Epoxy Busbar Support Insulators

- 25kv Pantograph Epoxy Insulator For Railways

- Epoxy Electrical Insulators

- High Current Bushing

- Insulating Base

- Epoxy Insulator

- Switchgear Insulators

- Support Insulator

- Contact Us

Quality

Quality is one such factor which contributes the most in the overall growth and success of any company. Keeping the same in mind, we strive to manufacture and offer only those Switchgears, Insulators, Surge Arresters Insulator Base, Bushings for Indoor/Outdoor Electrical Applications, Surge Arresters Disconnecters, etc. that are in complete abidance with international quality norms. Superior quality resin, MS metal parts, SS metal parts and other raw material are sourced by us from pioneering vendors for making our product-line. We have a team of quality controllers, who not only supervise production stages to evict chances of occurring defects but also test developed products to assure flawlessness. Our products are gauged on the grounds of their construction, dimensional accuracy, insulation ability, durability etc.We have invested on owning following quality testing facility for gauging our entire product range:

- High Voltage Testing Facility- 5 kV and 100kV

- Bending Load testing facility- 5 Tons

- Hydraulic Test facility

- X-Ray test machine for checking internal defects

Such advanced testing facilities and stringent quality controlling measures have enabled us to gain ISO 9001:2008 accreditation.

Products We Offer

Our firm manufactures and exports below cited products:

- Resin

- Epoxy Resin

- Insulation Materials

- Polyconcrete & Polymeric Insulators

- Switchgears Insulator

- Surge Arresters Insulator Base

- Distribution Line Fuse Cut Out

- Distribution Line Polymeric Insulator

- Bushing

- Bushings for Indoor/Outdoor Electrical Applications

- Bushing for Transformers

- Bushing for Windmills

- Bushing for Instrument Transformers

- Bushing for Railways

- Bushing for Load Break Switches

- Bushing for Surge Counter Bush

- Adhesives & Sealants

- Metal Parts

- Accessories

- Surge Arresters Disconnecters

- ZnO Block

Core Competencies

Our more than 10 years of experience makes us specialized in manufacturing and exporting different kind of electrical components such as Industrial Insulators and Electrical Bushings. We have the facilities, expertise and workforce that help us produce a range of quality, innovative and economical industrial products. Our core competencies include:

- Qualitative products at reasonable costs

- Excellent processing and testing facilities

- Focused on customers requirements

- Best industrial practices and global quality standards

Sound Infrastructure Set Up

Built over a massive land area, a modern & well-equipped infrastructure facility is developed to execute all the production and post-production activities in a streamline manner. We have maintained varied specific departments like manufacturing, quality evaluating, R&D and storage so that all trade operations can be executed in a streamlined manner. Our manufacturing wing is our backbone it enables us in making offered resin, insulation material, bushing, adhesive & sealants etc. in a commendable manner. Following are some of the facilities that are developed and maintained by us:

- Equipment that can cast all polymer resins for insulators

- High Power Vacuum mixing

- Hot Air Ovens for accommodating any quantities of insulators

- Material handling equipment for efficient production cycle

- Pressure Gelation machines capable of processing 10 Ton material per day

- Steam Chamber & Water Curing tank for Cementing of Porcelain Insulators

Patronage

We help create effective electric power systems. Keeping the concepts of safety, control and reliability in mind, we offer the best possible Switchgear and allied Products. With a broad range of Electrical Products, we serve for industrial projects, industrial works, domestic & commercial buildings etc. Our patronage includes:

- Adani Group

- ABB

- Ahemedabad Elec. Co.

- Alembic Glass Ind. Ltd.

- Areva T&D India Ltd.

- BSES

- Best & Crompton Engg. Limited

- Birla VXL LTD.

- Essar Group

- Kalpa Taru

- Reliance Energy

- Siemens

- Torrent Power Limited

Management Team & Personnel

- Mr. Aashish C. Dholakia: BE, Computer Engg. is having almost 25 years of working experience in the field of Polymers.

- Mr. C. G. Dholakia: BE, Chemical Engg. 30 Years of experience in the field of Polymers. Consultant and Project Initiator.

- Mr. Dharmendra Patel: BE Mechanical, 25 years experience in moulds making & process development. He is the products' quality in charge.

- Mr. Hitesh Patel: BE Mech. Tool Designing & Manufacturing.

- Mr. Dhaval: Diploma, Mechanical. Supervisor for last 10 Years. He is responsible for in-process control and testing of the products.

- Mr. Rakesh Doshi: Graduate, responsible for Stores & Incoming Inspection.

- Mr. Vipul Pancholi: Purchase & sourcing

- Mr. Gopal Vaghela: Technician, 25 years experience in production. He takes care of the production parameters, and in-process checks.

- Mr. Aashish Shah & Mr. Uday: MBA, Marketing Associates.

Plus, we are supported by dedicated vendors who are with us for years. Also, we will increase quality inspectors in near future, for incoming / outgoing material. And testing engineers as well as new product developers.

Operations- Overview

- Factory Land Area: 11,000 Sq. Ft. (SI), 10,000 (RI), 10,000 (RE Unit 1), and 38,000 Sq. Ft. (RE - Unit 2)

- Shed Area: 5000 Sq. Ft. (SI), 5000 Sq. Ft. (RI), 4000 Sq. Ft. (RE Unit 1), and 5000 Sq. Ft. (RE Unit 2)

- Molding Machines: 30 Nos (17 Manual & 3 Semi Automatic), good enough to process 5 Tons of materials in 24 hour shift / 5000 Nos. 33kV Insulators every month.

- Vibratory Molding Machines: 5 Nos, Can process 600 Kgs in 24 Hour shift.

- Electrical Testing equipment: 100kV

- High-Capacity Vacuum Pumps: 4 Nos

- Pressure Testing Machine: Upto 60kG/cm2

- Cantilever Testing machine: Upto 2 Tons

- Steam Chamber: 1 No, Can process 22 Nos Insulators

- Hot Air oven: 4 Nos

- Plastic Injection Molding Machines: 1 Nos

- Arrester Crimping machines: 1 Nos, for 1000 Units / day

- Disconnector Assembly Units: 20 Nos and Resin Manufacturing plants: 200 Ltr.

Financial Forecast

Turnover of our group for this year has been Rs. 6,50,00,000/ - in which, we sold:

- 4,50,000 Nos. Disconnectors

- 1,49,000 Nos. Insulating Bases-Arresters.

- 3500 Nos. Transformer Bushings

- 2000 Nos. Windmill Bushings

- 3200 Nos. Porcelain Cemented Bushings

- Insulators upto 72kV

- 2,00,000 Nos Zinc Oxide Discs (sourced from china)

Our Target for Next Year is:

- 5,50,000 Nos. Disconnectors

- 1,56,000 Nos. Insulating Bases for arresters

- 3,00,000 Nos. Discs

- 35000 Nos. support-insulators for switchgear plants

- 4500 Nos. Bushings for Transformers & Capacitors

- 5000 Nos. Windmill Bushings

- 1200 Nos. Porcelain Cemented bushings

We also market many other products such as Fuse Cut Out, Insulators, and allied products sourced from different countries.

Click here for more details: | Part 1 | Part 2 |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese